Location: Los Angeles, California

Architects: Diller Scofidio + Renfro

Lighting Design: ARUP (Gallery Lighting Engineers)

Illuminating the Veil & Vault at the Broad Museum

Located in Downtown Los Angeles, California, the Broad Museum showcases a collection of contemporary art from the 1950s in both permanent and rotating galleries. Opened in 2008 by Philanthropists Eli and Edythe Broad, the museum works to advance education and engagement through their exhibitions and art lending program.

The Broad Museum was designed by Diller Scofidio + Renfro in collaboration with Gensler. The space features two floors of gallery space, and was designed to house a split program of public exhibition spaces and a private lending art library. To merge these two spaces together, DS+R developed a “veil and vault” approach.

The “veil and vault” was designed to integrate both the public exhibition space and collection storage in the museum. The curved underside of the “vault” carves out the lobby of the museum, and the top surface is also used as the first floor of exhibition space. The lending library is located inside of the “vault,” and the dark mass features windows to show visitors the extensiveness of the collection.

Both the “vault” and exhibition space are enveloped by the “veil,” a delicate meshwork structure that surrounds the outside of the gallery. The honeycomb-like “veil” helps synthesize the program of the vault, while also allowing natural light into the museum. The veil gives the ceilings in the exhibition spaces their unique geometry. At over 25’ in height, the exhibition spaces are expansive, and capable of supporting monumental art exhibitions.

The Challenge

In 2015, high-output LED fixtures with high CRI were fairly rare. To achieve both high-output and high CRI typically required a very large heatsink to move heat away from the thermally sensitive LED. The Broad had ceiling heights up to 24’, and wanted an even ceiling to floor wallwash in its galleries.

The initial challenge of providing a very high-output fixture was compounded by two additional requirements: 1) the need to spread the light evenly over a very tall surface, which requires special optical control; 2) the need to make the fixtures compatible with another manufacturers’ track.

Lighting such a tall space requires a very high-output LED, which can quickly cause troubles when it comes to heat generation and energy use. It was soon understood that the museum needed to develop a solution that would illuminate the space, while also maintaining the LED’s within the thermal tolerance.

The Process

The client came to Litelab because the originally specified fixtures could not meet the distribution and light levels desired by the institution. At the time, providing such high light levels with very high CRI was very difficult; we explored a number of options related to the light sources and thermal management system, each time testing to see if the fixture met the specification and was maintained within the required thermal parameters.

When exploring the options, we came across multiple difficulties with potential solutions: first, there were different chip sets and optical configurations that didn’t meet the requirements for either distribution, CRI, or output; second, there were a number of different thermal management systems that didn’t meet the requirements of the system as a whole; third, we also had to develop several types of fitters to ensure that the track and fitter combination could sustain the weight of the fixture, since it was rather large, despite efforts to miniaturize as best as possible given available technologies.

Heat was the most difficult challenge to overcome; it represented a cascade of challenges. We wanted to keep the fixture as small as possible, but the size and performance aspects of the fixture were in direct opposition to the thermal management component of the design. Once we established a viable small-scale thermal management solution, other elements of the design could be finalized.

Whenever we develop a custom solution, the considerations are similar. They involve a combination of aesthetic considerations (we wanted the fixtures to be as small as possible, and to be as minimalistic as possible — we believe that focus should be on what is illuminated, not what is providing the illumination, especially in cultural contexts, like the Broad), and performance. Balancing size and aesthetic with performance can be a serious challenge, and we worked closely with the Broad to ensure that the fixture met both.

The Solution

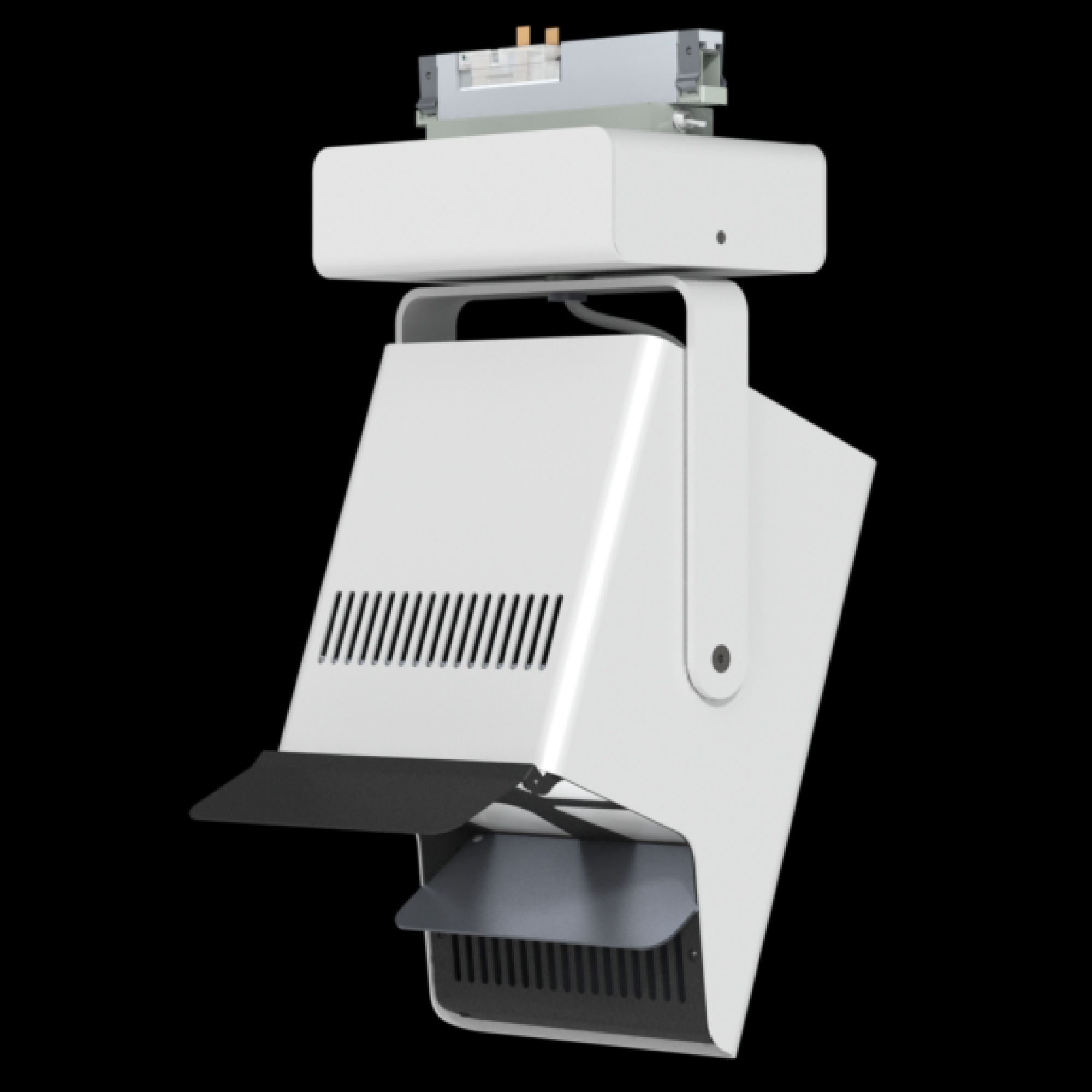

The museum needed a very high-output fixture to provide even distribution on walls up to 24’ tall with fairly high light levels. They wanted the fixture to be as small as possible, given the performance requirements, and they wanted a fixture with maximum control in terms of light levels and distribution.

The M78 met all of those requirements, and to complement the M78 in areas with lower ceilings, Litelab also created the M97 and M98. These use the same chip-set as the M78 to ensure consistency of color characteristics and rendering. The latter produce 3000 Lumens, and are in the more traditional cylindrical format. The result was a family of fixtures that addressed the variety of lighting requirements at the museum, tailor-made to the museum’s lighting requirements.

To manage the heat, we realized that traditional heat dissipation systems couldn’t move heat away from the sources quickly enough, and researched alternative methods from different industries that have similar thermal and size requirements. Using heat dissipation technology taken from supercomputers, we were able to provide a fixture that produces 12,000 Lumens — one of the most powerful (if not the most powerful) LED wallwasher on the market.

In addition to providing a family of high-output, high-CRI fixtures, Litelab also developed a fitter compatible with an alternative vendor’s infrastructure. In doing so, we learned the value of these kinds of offerings. Infrastructure is frequently a permanent attribute of the building, and changing it is very difficult, and time, labor and resource intensive.

Compatibility with multiple different styles of track is becoming increasingly important, due to volatility in our marketplace. This can mean that popular providers for museums and other institutions can go out of business, or reduce certain fixture lines, leaving museums and institutions wanting for new fixtures to replace older ones. In the past several years, Litelab has developed fitters for compatibility with many different styles of track, allowing institutions the option of using our fixtures regardless of the existing infrastructure.